The Value of Quality in the Production of Copper Products

The relevance of top quality in the production of copper products extends far past mere compliance; it is essential to maximizing efficiency across different industries. Top notch copper not just enhances conductivity however likewise guarantees resilience and integrity, which are critical in applications ranging from electronic devices to auto systems. Nonetheless, the effects of bad production practices can reverberate via costs and security requirements, eventually affecting client trust. As we explore the complex nature of top quality, the inquiry emerges: how can producers stabilize these challenges to accomplish quality?

Effect On Product Efficiency

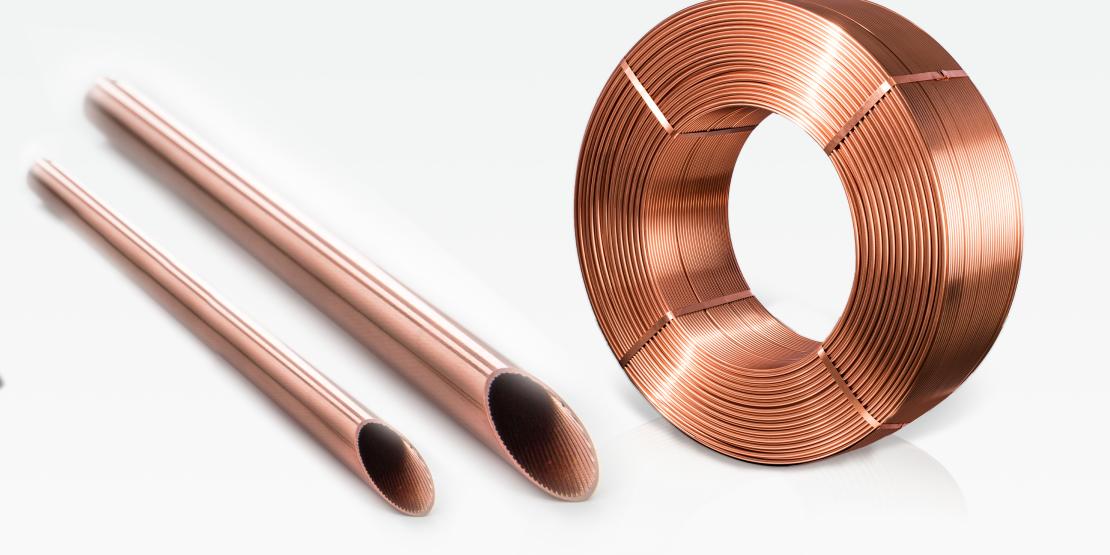

The top quality of copper products plays an important function in determining their overall performance in different applications. Top quality copper exhibits exceptional electric conductivity, thermal conductivity, and corrosion resistance, which are necessary attributes for sectors such as electronic devices, building, and vehicle.

Furthermore, the mechanical properties of copper, consisting of ductility and tensile stamina, substantially influence its efficiency in manufacturing procedures. Copper products that meet stringent top quality standards can stand up to substantial stress without warping, therefore improving durability and reducing the possibility of failing sought after atmospheres.

Furthermore, the surface coating of copper items impacts their efficiency. A smooth, well-treated surface can prevent oxidation and various other kinds of deterioration, inevitably prolonging the life of the part. In recap, the quality of copper products straight impacts their capability, integrity, and longevity throughout numerous markets, making it crucial for makers to follow strenuous quality assurance procedures throughout the production procedure.

Price Effects mediocre

Purchasing top quality copper products is essential, as the expense implications of bad quality can be substantial for end-users and makers alike. Poor high quality copper can lead to boosted failing prices, resulting in pricey repairs and replacements. Manufacturers might encounter substantial downtime as faulty items require remembers or rework, interfering with production timetables and affecting general efficiency.

From an end-user viewpoint, the ramifications are just as serious. Poor-quality copper can cause inefficiencies and enhanced functional costs, as equipment might call for even more regular upkeep. Inevitably, the first savings gained from picking lower-quality copper products can be outweighed by these long-term expenses, making the quest of quality not just a matter of performance, but a vital economic factor to consider in the manufacturing field.

Safety and Conformity Standards

Guaranteeing safety and security and compliance criteria in the production of copper items is vital to preserving functional stability and safeguarding both employees and customers. The production procedure should follow rigid policies stated by organizations such as the Occupational Security and Health Administration (OSHA) and the Environmental This Site Defense Company (EPA) These regulations detail crucial safety methods, consisting of proper handling of resources and waste monitoring, guaranteeing a secure job setting.

Furthermore, compliance with sector standards such as ASTM International and ISO certification is vital. These companies supply standards that assist makers carry out finest techniques in quality assurance and safety steps. Normal audits and evaluations ought to be conducted to make sure adherence to these standards, as non-compliance can lead to harmful problems and prospective legal implications.

Consumer Depend On and Fulfillment

Trust fund and complete satisfaction among consumers play a critical role in the success of copper item suppliers (Copper Products). Premium copper products not just satisfy rigorous market requirements but likewise accomplish consumer assumptions, promoting loyalty and repeat company. When customers are confident in the high quality of the products they purchase, they are more probable to establish a lasting connection with the maker, which can lead to recommendations and positive word-of-mouth

To construct this look here trust, makers have to focus on quality assurance throughout the production procedure, ensuring that each copper product meets or exceeds requirements. Transparency in producing methods, coupled with dedication to consumer solution, reinforces the understanding of reliability. Timely delivery and responsiveness to consumer inquiries substantially enhance contentment levels.

Client comments should be proactively looked for and incorporated into product development cycles to continuously improve offerings. Involving consumers in discussion regarding their demands and choices cultivates a sense of collaboration, additional solidifying their rely on the supplier. Eventually, an online reputation for high quality and customer-centric techniques distinguishes successful copper product suppliers in an open market, laying the groundwork for withstanding consumer partnerships.

Lasting Service Success

A maker's dedication to top quality is essential to achieving long-term organization success in the affordable copper products market. High-quality items foster consumer commitment, ensuring repeat business and favorable recommendations that drive growth. In a sector where dependability and performance are critical, firms that prioritize quality over cost-cutting actions are more probable to stand out.

Additionally, regular top quality reduces the occurrence of defects and revamp, causing lower operational costs and raised efficiency. This streamlined production procedure enables suppliers to allot resources properly, enabling financial investments in technology and technology. Services that adjust to market adjustments and invest in high quality improvements are better placed to fulfill evolving client demands.

Furthermore, preserving rigid quality standards enhances a business's reputation, bring in prospective collaborations and brand-new clients. A durable reputation for high quality can act as a differentiator in congested markets, opening doors to lucrative agreements and cooperations.

Eventually, an unwavering commitment to high quality not only makes sure compliance with sector guidelines but additionally cultivates a sustainable organization version. By embedding top quality into every element of the production process, business can safeguard their place as leaders in the copper products sector, paving the method for withstanding success.

Verdict

In final thought, the importance of top quality in copper product manufacturing is paramount. As sectors increasingly depend on copper for important applications, maintaining strenuous high quality control is imperative to safeguard an affordable advantage and copyright a respectable market presence.

The relevance of quality in the read production of copper items expands far past simple conformity; it is essential to maximizing performance across different sectors. In summary, the high quality of copper products directly influences their functionality, dependability, and long life across numerous industries, making it essential for makers to stick to strenuous quality control steps throughout the manufacturing process.

A maker's commitment to top quality is indispensable to accomplishing lasting organization success in the affordable copper products market.